The world of manufacturing is constantly evolving and changing. And 3D printers may be the next big step.

3D printing, or additive manufacturing, is a process that allows for a three-dimensional solid object to be created from a digital file. For years, when the technology was first introduced, it appeared to be more of a novelty than a practical tool, creating one-off trinkets and souvenirs. But now, with lower costs and technological advances, 3D printing is within more people’s reach and has already been used in a number of interesting ways, ranging from medical applications to shoe production.

But like any other relatively new technological advancements, there are both pros and potential drawbacks. Here we examine those consequences, and look at where 3D printing is now and where it might be headed.

The current state of things

The 3D printing market has been steadily growing over the years. The primary market, including 3D printing systems, materials, supplies, and services, has grown at least 30 per cent each year from 2012 to 2014, according to a report published by the Consumer Technology Association (CTA) and the United Parcel Service (UPS).

The report, titled “3D Printing: The Next Revolution in Industrial Manufacturing,” found that two thirds of manufacturers already use 3D printing in some way, and 25 per cent had plans to adopt the technology in the future. Corporations cited prototyping, product development, and innovation as their top reasons for using 3D printing.

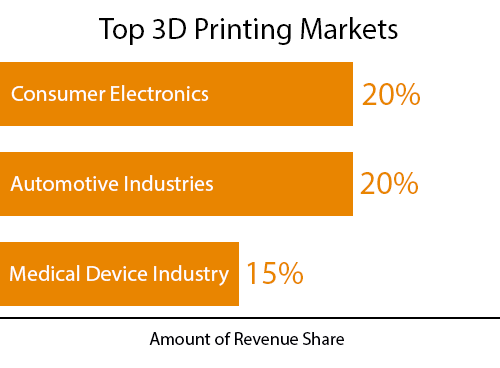

The consumer electronics and automotive industries each contribute 20 per cent of the total 3D printing revenue, using the technology primarily during the prototyping phase of production, according to the report published by the CTA and UPS. But some are expanding outside of just prototyping. For instance, smartphone manufacturers have begun using 3D printing for some component parts.

The medical industry is the third largest 3D printing market, contributing 15 per cent of the total 3D printing revenue. The industry uses the technology for mass customized finished goods, such as hearing aids. 98 per cent of hearing aids worldwide are now manufactured using 3D printing.

Despite all of this, 3D printing has not taken over much of the manufacturing landscape, with less than one per cent of all manufacturing output being 3D printed today.

Currently, less than one per cent of all manufacturing output is being 3D printed.

The arguments for and against

Currently, 3D printing is most commonly used for producing prototypes because changes are typically easier and cheaper to make compared with having to reset tools in a factory. The technology is ideal for low-volume production, such as craft items like jewellery or customized products like prosthetics. Dental crowns and hearing aid buds are already being made by the million with 3D printers.

It’s also great for producing lightweight and complex shapes for high-value products ranging from aircrafts to racing cars. This is because the printer deposits material only where it’s needed. GE has already spent $1.5 billion on the technology in order to make jet engine parts, among other things.

But some believe that 3D printing may never be fully embraced by the manufacturing industry because it’s so time consuming; some complex items can take up to two days to create. Currently, the cost of equipment and materials for 3D printing is also quite high, and the choice of materials available is a fraction of the variety used in conventional methods.

During a keynote presentation at the Canadian Manufacturing Technology Show, Kirk Rogers, technology lead at the GE Center for Additive Technology in Pittsburgh, warned that additive manufacturing may not supplant traditional manufacturing entirely. Of the parts GE makes at additive manufacturing centers, he said, 85 per cent have required traditional manufacturing technologies, like machining.

What the future could hold

While 3D printing may not be taking over the entire manufacturing industry just yet, analysts predict there will be a great deal of growth and the market will be worth 32.78 billion USD by 2023.

Analysts have predicted the 3D printing industry will be worth 32.7 billion USD by 2023.

Many manufacturers have already started to explore the market to see what potential may be there. Adidas, for instance, has started to use a form of 3D printing called “digital light synthesis” in order to produce the soles of trainers, pulling them fully formed from a vat of liquid polymer. This method will be used in some new Adidas factories in Germany and America in order to produce one million pairs of shoes annually to market more quickly than conventional processes would allow.

The economics of metal printing could be changed by 3D printing too, with a new technique called bound-metal deposition. The technique can build objects at a rate of 500 cubic inches an hour compared to one to two cubic inches an hour when using a typical laser-based metal printer.

The full consequences of 3D printing in the manufacturing industry are hard to predict. But based on what’s happened already in the industry and what analysts expect to see in the coming years, it seems safe to say that we haven’t seen 3D printing used to its full potential just yet.

Want to learn more about current trends in manufacturing? Check out our blog on the topic! Or visit our Manufacturers’ Insurance page and find out how our experts can help your business today!